|

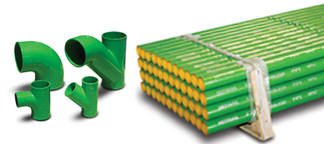

EPOXY COATED NO-HUB PIPE & FITTINGS

|

EPOXY COATED SERVICE WEIGHT PIPE & FITTINGS

|

NewAge Casting Headquarters • 12630 West Airport Blvd. • Ste. 100 • Sugar Land, TX 77478

Toll Free: (866) 791-7055 • Tel: (281) 565-0928 • Fax: (281) 565-0929 • Email: [email protected]

Toll Free: (866) 791-7055 • Tel: (281) 565-0928 • Fax: (281) 565-0929 • Email: [email protected]

Copyright © 2022 NewAge Casting - All rights reserved.